Skip to content

"Supply chain inventory Optimisation is defined as a method of balancing ones capital investment constraints and goals along with the defined service-level goals over a large assortment of stock-keeping units (SKUs) while considering all demand and supply volatility situations. It includes the practice of having the right levels of inventory to meet your target service levels while keeping a minimum amount of capital locked for inventory."

"Supply chain inventory Optimisation is defined as a method of balancing ones capital investment constraints and goals along with the defined service-level goals over a large assortment of stock-keeping units (SKUs) while considering all demand and supply volatility situations. It includes the practice of having the right levels of inventory to meet your target service levels while keeping a minimum amount of capital locked for inventory."

Inventory optimisation is also considered as the next level of inventory management for warehouse and supply chain managers. Which is why, manufacturers can achieve holistic Inventory Optimisation, by considering both supply and demand fluctuations and minimizing excessive inventory.

Supply chain inventory Optimisation can easily help manufacturers overcome warehouse management and stocking problems with reduced inventory. Studies show that almost 65% of damaged inventory ends up that way due to the incorrect method of packing, storing, or securing in freight containers. Inventory optimization can help overcome these errors to a large extent. With accurate Inventory Optimisation, distribution and manufacturing can streamline working capital requirements and stocking issues using predictive analytics and data-driven insights.

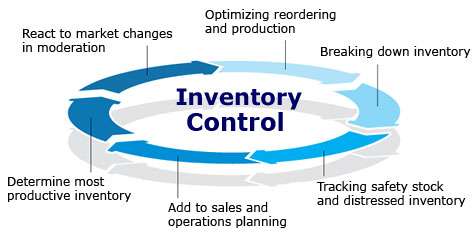

Simple definition of aims for Inventory Optimisation in the SME.