MYOB Acumatica Manufacturing Software

A comprehensive manufacturing ERP solution tailored for Australian businesses. With integrated and interconnected features spanning every aspect of manufacturing operations, MYOB Acumatica is designed to enhance profitability, streamline resource management, and minimise expenses. Engineered for contemporary technology, this cloud-based platform boasts an open architecture, enabling seamless integrations, scalability, and user-friendly operation.

MYOB Acumatica Cloud Manufacturing ERP

MYOB Advanced Manufacturing Software offers specialised software for manufacturing companies, specifically for the discrete manufacturing industry.

Integrated seamlessly with MYOB Acumatica Financial Management, Distribution Management, Customer Management, and Project Accounting Suites; Manufacturing provides real-time coordination of all your business activities from one central location.

MYOB Acumatica Manufacturing has created two additional modules that can be utilised, Estimating and Product Configurator.

The Estimating solution creates estimates for new or existing items that can be converted into bills of material, production orders, and/or another estimate.

The Product Configurator is a multi-level, dimensional, rules-based system with non-hierarchical feature selections and configuration evaluation. It allows the user to configure a product’s features, options, and dimensions to maximise the quote-to-order process.

.png)

Listen to Acumatica!

Whilst licensing approaches are different for Australia, the cost of an unlimited user platform is outweighed by MYOB license per user approach thus eliminating the barrier to entry.

MYOB Acumatica Manufacturing Management

The MYOB Acumatica solution is a complete, multi-site manufacturing control and planning system for make-to-stock, make-to-order, engineer-to-order, project-centric, job shop, batch, and repetitive manufacturing.

Integrate production planning and shop floor with customer management, sales orders, inventory, purchasing, accounting, and financial reporting to provide real-time coordination of activities across your entire business.

Benefits of MYOB Acumatica Manufacturing

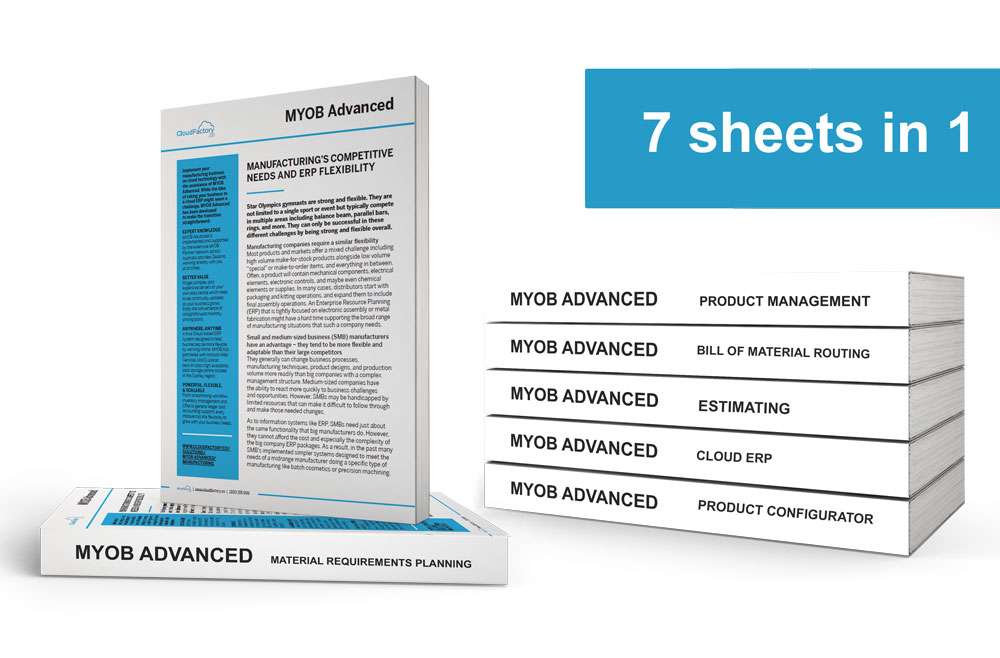

7-IN-1

MYOB Acumatica Manufacturing Fact Sheets

While the idea of taking your business to a cloud ERP might seem a challenge, MYOB Advanced Manufacturing has been developed to make the transition straightforward.These factsheets cover topics of

-

Bill of Material

-

Estimating

-

ERP flexibility

-

Material Requirements Planning

-

Product Configurator

-

Production Management & more!

Bill of Materials and Routing

Efficiently plan and manage inventories, costs and manufacturing processes as well as full revision control. See both engineering and financial views of product structure in the multi-level Bill of Material (BOM)/Routing.

Product Configuration

A multi-level, dimensional, rules-based system with non-hierarchical feature selections and configuration evaluation. Use on quotes, sales orders, and/or production orders with real-time price and cost roll-up.

Production Management

Schedule production on the shop floor and track material and labour costs. Compare standard/planned production costs to the actual costs of the production order.

Material Requirements Planning

Satisfy customer requirements while maintaining an optimal inventory with the powerful features within the MYOB Advanced MRP planning tool.

Estimating

Create estimates for new or existing items, convert into bills of material, production orders, and/or another estimate.

Planning and Scheduling

MYOB Advanced Planning and Scheduling capability allows users to accurately schedule work centres, machines and tooling resources. The system must also accurately determine the requirements for materials and capacity while providing resource utilisation and efficiency reporting for expensive capital equipment

Grows with you

Powerful and complete functionality for make-to-stock, make-to-order, engineer-to-order, project-centric, job shop, batch, and repetitive manufacturing adapts to your business as you grow and change.

Meet your schedule

Respond to demand while optimising inventory and resources for effectiveness and cost control with MYOB Advanced MRP planning.

Track your costs

Track material and labour costs as you manage your products.

One Solution for all your business

MYOB Advanced Manufacturing is a feature-rich manufacturing solution. It delivers powerful and comprehensive functionality for make-to-stock, make-to-order, engineer-to-order, project-centric, job shop, batch, and repetitive manufacturing companies.